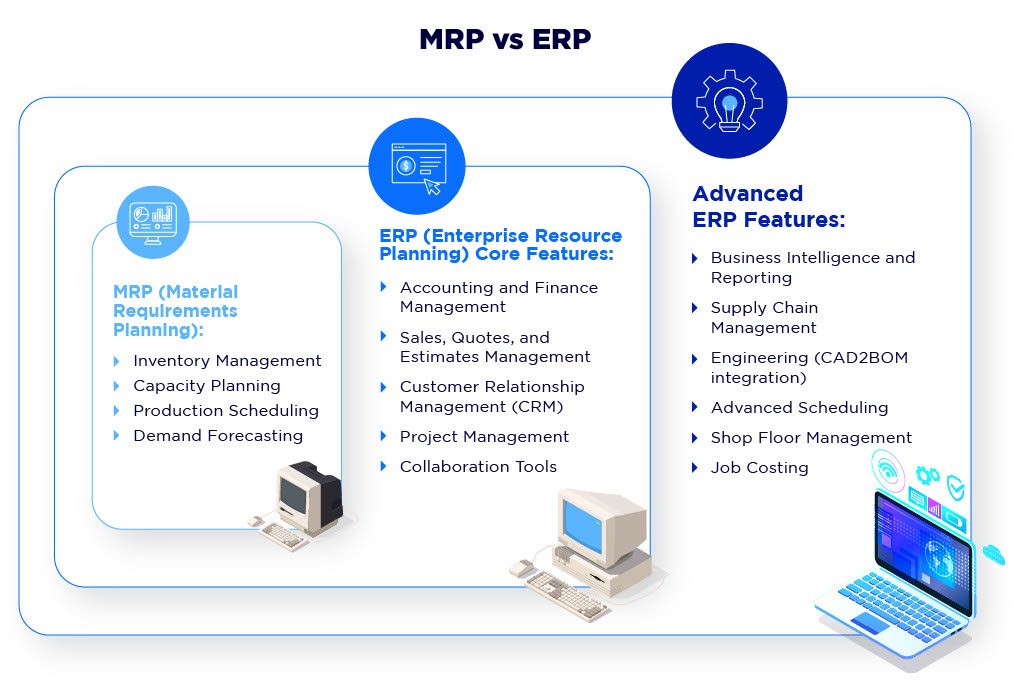

MRPs (Material Requirements Planning) are a great way for manufacturers to manage their shops and include inventory, capacity planning, and scheduling features. However, ERPs (Enterprise Resource Planning) are an even better way for manufacturers to take control of their shops.

ERPs are a more complete software system — including all of the features of an MRP — but also let manufacturers improve and manage their sales, quotes and estimates, customer relationship management, accounting, human resources, project management, and much, much more.

People often get these two terms confused and it’s easy to see why: the acronyms are similar and ERPs and MRPs share the same history. But even though the two are intertwined, they are two separate entities and each will give you different levels of performance and capabilities. Read on below to get a more complete understanding of the difference between ERPs and MRPs.

MRP = Material Requirements Planning

MRP stands for Material Requirements Planning and is a software solution that helps manufacturers calculate more precisely what materials they require, at what time, and in what quantities. Over time MRPs developed more functionalities and most MRPs (known as MRP II) now include detailed capacity planning, scheduling, shop floor control, and other calculations. MRP II gives you the ability to compare forecasts with actual data, analyze performance and improve processes to achieve better efficiency.

ERP = Enterprise Resource Planning

ERP, on the other hand, stands for Enterprise Resource Planning and is a more complete software system that includes additional features and functionalities to help manufacturers automate and streamline business processes, not just related to manufacturing, but across their entire enterprise. ERPs developed out of MRPs and are designed to not only help manufacturers better plan their inventory and scheduling, but to help manufacturers with sales, quotes and estimates, customer relationship management, accounting, human resources, project management, and more.

ERPs go beyond MRPs and connect and integrate all the different aspects of your business into one database, allowing you to streamline tasks and processes, as well as share error-free information across your entire organization. ERPs power your business with accurate data, and help you to increase efficiencies and reduce costs across your organization.

In short, ERPs do it all, whereas MRPs are more specific to manufacturing processes.